Passion that puts things in motion.

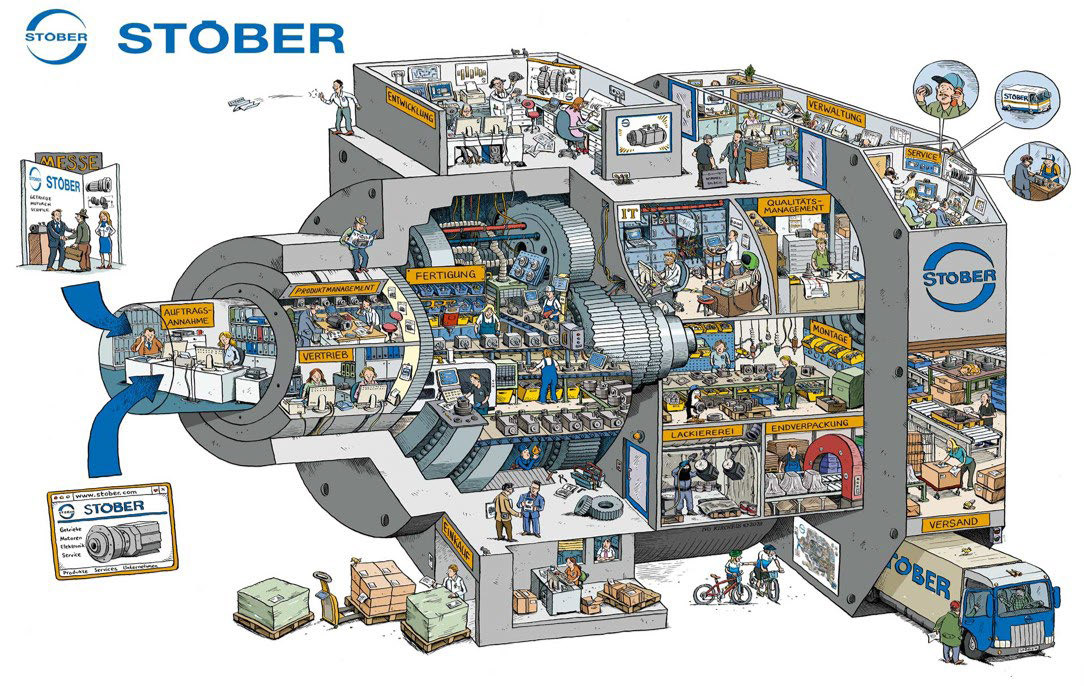

As an international, medium-sized company, we have stayed true to our roots and are looking forward to the future with confidence. Our gears are turning smoothly when new ideas bring about the technologies of the future.

Why does this work? At our company, everyone has the chance to contribute, in an open atmosphere of appreciation and mutual respect. Here, everyone can rely on each other, because by pulling together, we can keep things moving. It just makes sense that we prefer to give our skilled workers a long-term home.

What counts here is each person, their talents, and what drives them at every career level.

As a family-owned company, close relationshipsare extremely important to us. We build relationships with our employees, customers, and partners based on trust. We put people first.

Learn more about our vision and mission as well as our values. WE ARE STOBER. Empathic. Committed. Like family.

STOBER was founded in 1934 by the brothers Paul and Wilhelm Stöber. Today, the company is still family-owned.

Together we move big

We are there for you

Have any questions?

+49 7231 5820

News from STOBER

- More market, less riskSTOBER focuses on balance in a world shaped by geopolitics.

- Successful lateral thinkingSTOBER’s advanced right-angle servo gearbox.

- Driven by trustSTOBER supports users with comprehensive customer service.

Get to know us

Take a look at our upcoming events.