PLASTICS MACHINES.

Plastic is one of the most versatile and adaptable materials in the world. In addition to demanding high productivity and energy efficiency, the requirements on machines for processing, preparing or recycling plastics also include high process accuracy.

Applications and Solutions for Plastics Machines

Whether extruders, injection molding, blow molding or handling machines – drive solutions from STOBER significantly increase the precision, product quality, productivity and dynamics of plastics machines:

Rack and pinion drives

STOBER rack and pinion drives featuring the highest gearing quality and power density for designing precise and dynamic machines. It’s a compact, easy-to-use system with process reliability.

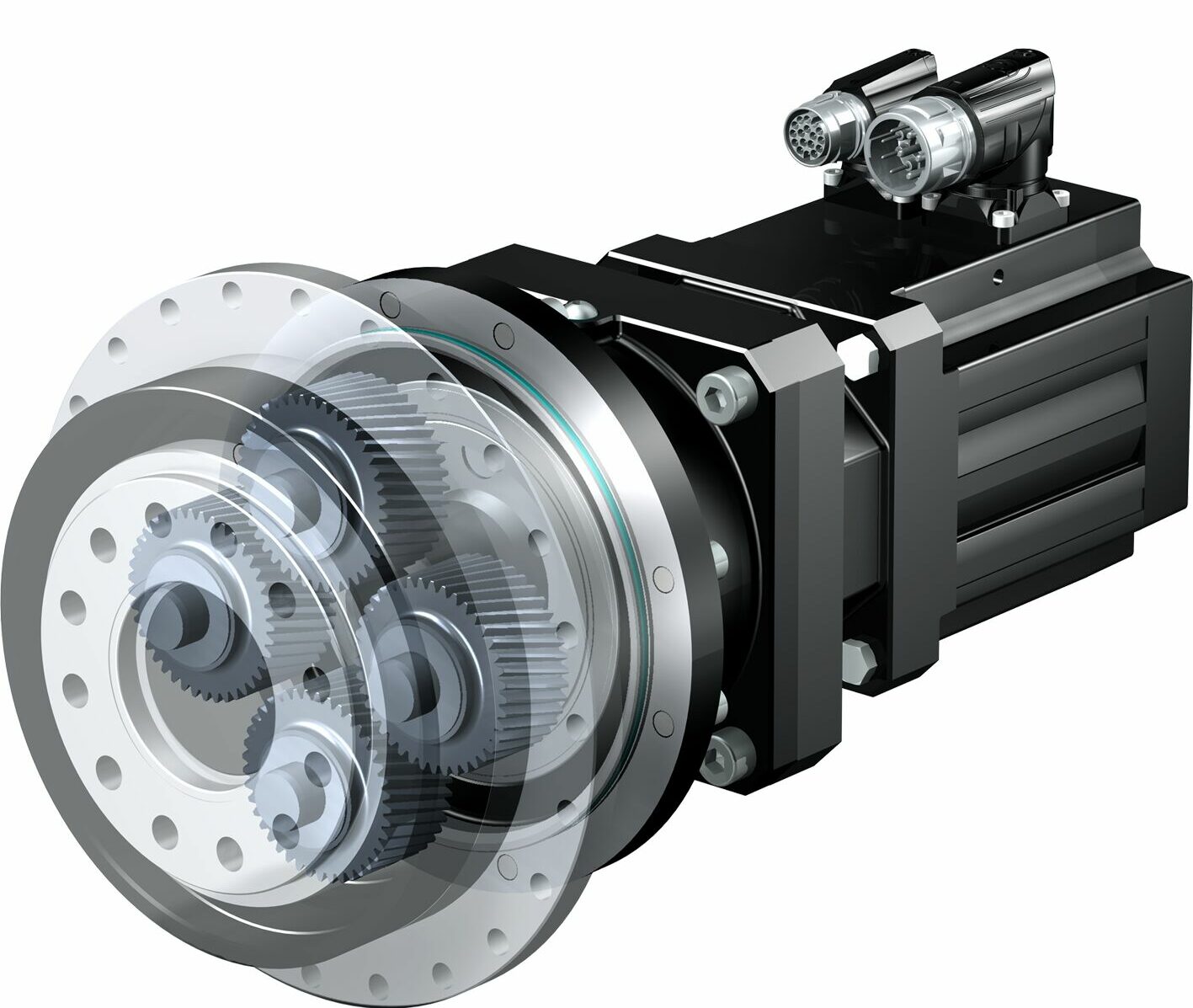

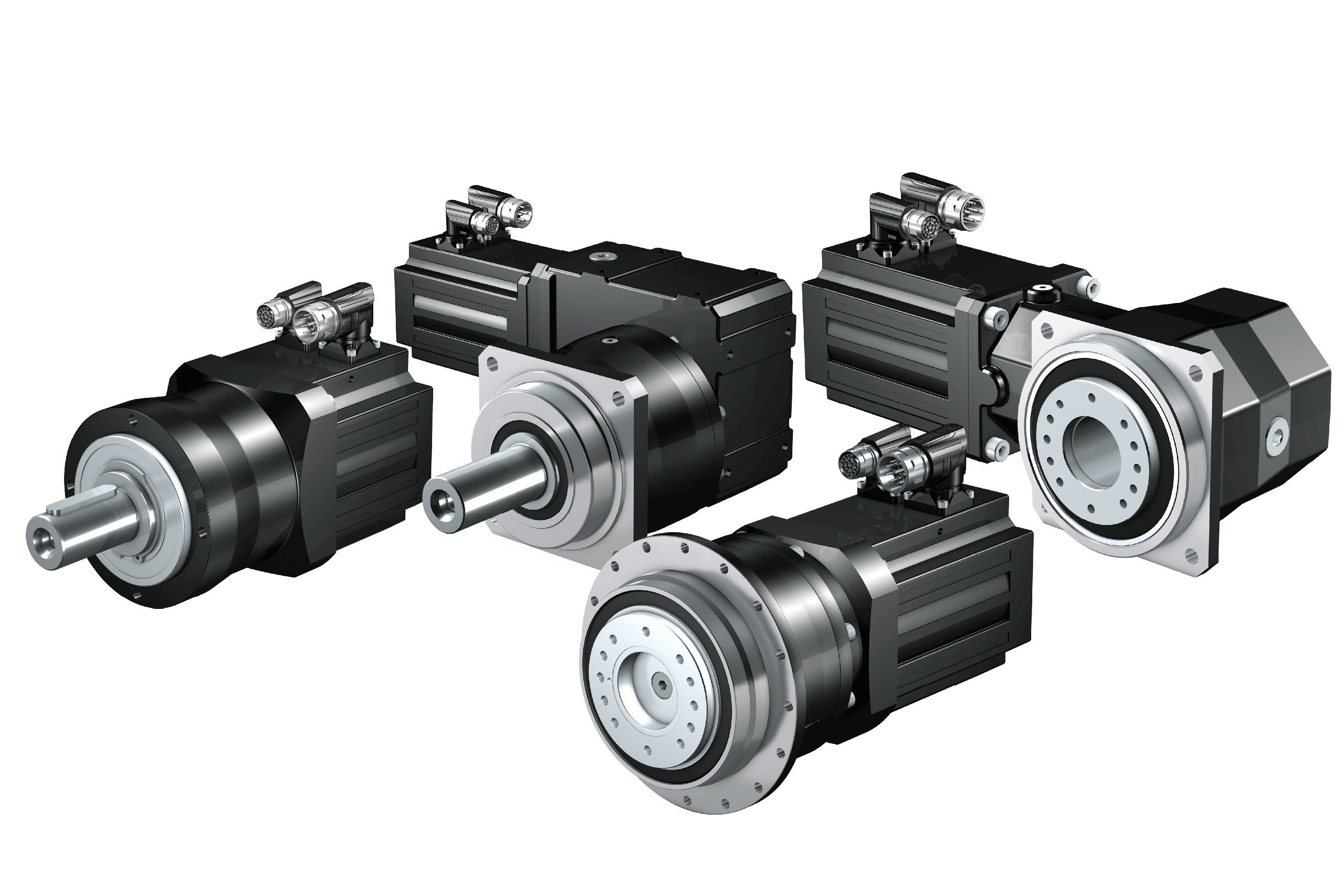

Low-backlash planetary gear units

For µm-precise positioning and maximum torsional stiffness. The high housing and gearing quality ensures high acceleration torques and also the highest running accuracy.

High-quality helical gearing

The high-quality helical gearing that is typical for STOBER is responsible for the low noise development and the best smooth operation – even at lowest feed velocities.

High gear ratio variance

For the best possible optimization of mass inertia ratios and for highly dynamic and accurate positioning.

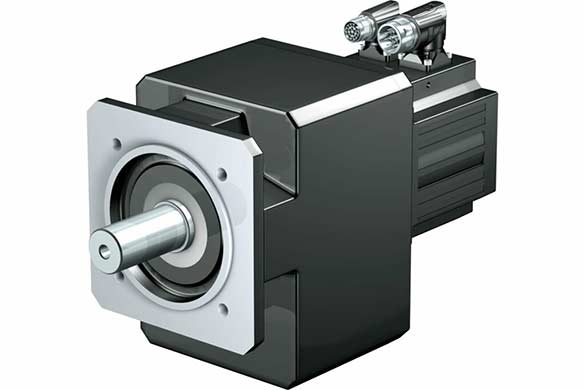

Large selection of coaxial and right-angle gear units

Benefit from an extraordinary variety of combinations and options – for maximum flexibility in design.

High-quality synthetic lubricants

All STOBER gear units are lubricated for life and maintenance-free.

Compact directly attached geared motors

Save costs and benefit from a lower mass inertia, higher dynamics and increased efficiency at the same time.

Super-compact synchronous servo motors

Our power packs are super-compact and deliver maximum torque combined with high dynamics! Available with a wide variety of encoders and holding brakes.

High-performance drive controllers

Tailor-made for any kind of drive task and with multiple certified safety functions – for the reliable protection of operator and machine.

Developed in-house and precisely coordinated: As a system manufacturer, STOBER implements drive solutions with maximum synergy efficiency. With STOBER, you gain a partner who makes a large contribution to achieving your goals:

✓ Increased productivity.

✓ Fail-safe operation and machine availability.

✓ Maximum dynamics in a reduced installation space.

✓ Reduced manufacturing costs.

✓ Maintenance-free.

✓ Energy efficiency.

✓ Sustainability.

Please contact us!

+49 7231 582-3060

systemsupport@stoeber.de

SERVOsoft®

Precisely scale drive systems in just a few steps. Simple and fast.

References