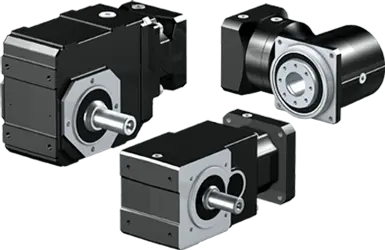

- Extended gear ratio range for a wide range of applications.

- Powerful. Flexible. Space-saving.

- • Robust, maintenance-free design for maximum reliability.

Drive Technology

Made in Germany.Since 1934.

Together, we can implement demanding movements.

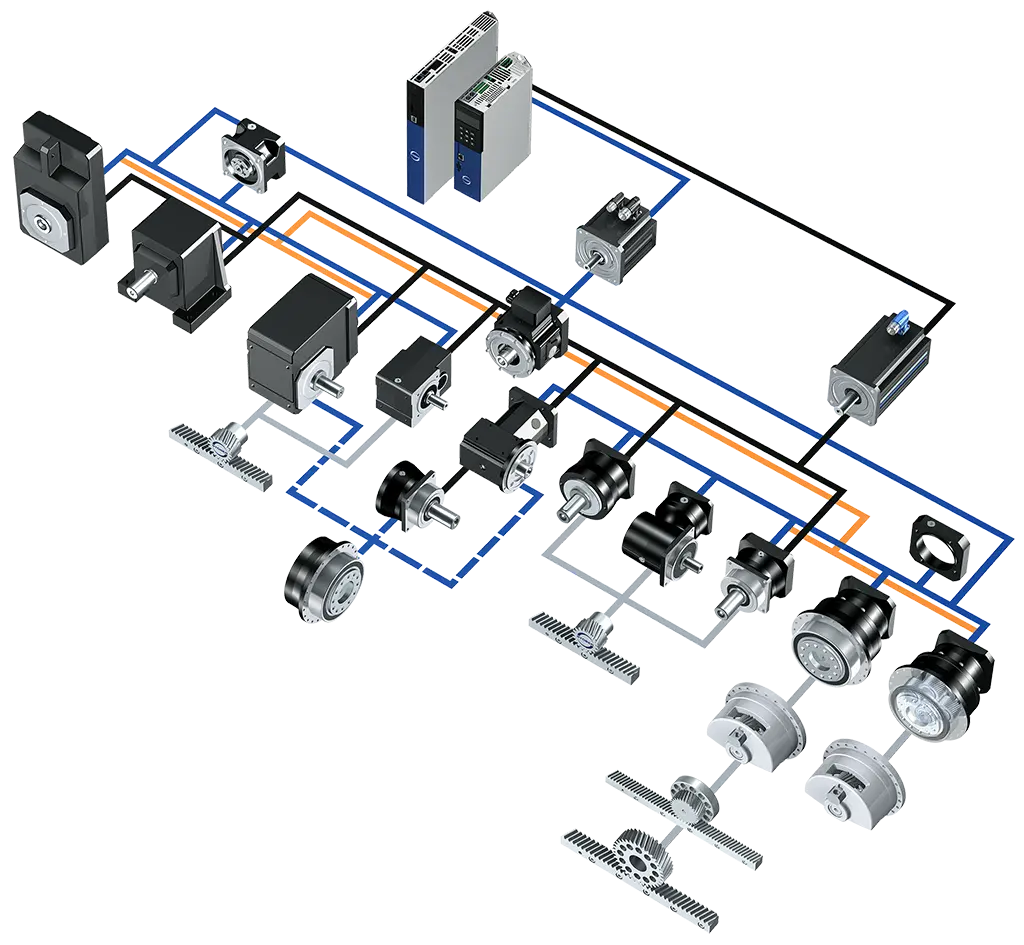

You get the benefit of our deep roots in gearbox manufacturing and our broad product portfolio, covering gearboxes, motors and matching drive controllers.

Our drive systems are modular and freely scalable – for tailor-made, compact and powerful machine concepts.

„We have installed gearboxes, motors and drive controllers from STOBER in nearly all our systems. STOBER drive technology has been there from the beginning and supports us in new projects from the first stroke of a pencil in the design phase until commissioning. Our years of cooperation are shaped by openness and honesty and emanate a rather special spirit. The technical consulting, the support – that is real, experienced partnership.”

– Jürgen Leicht, Managing Partner, Leicht Stanzautomation GmbH

News from STOBER

- International markets stabilize businessDespite the ongoing weakness of the market, STOBER is preparing for an upturn – particularly in automation and robotics – drawing on its international strengths, innovative solutions and stable team.

- Keeping Full ControlSOGA Gallenbach GmbH in Pforzheim, Germany, designs and develops special machines

- Greater safety in a small spaceSTOBER expands SB6 drive controller with the SX6 safety module.

Events

Get to know us and our drive technology

Get to know our company and our drive solutions better. The best way is on site. Take a look at our upcoming events and trade shows.