Successful lateral thinking.

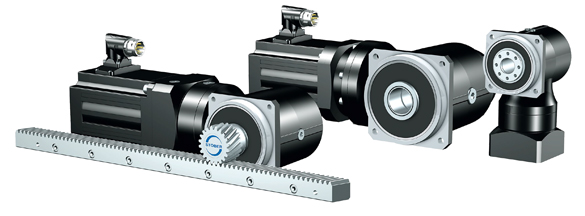

KS right-angle servo gearbox

STOBER has further developed its KS right-angle servo gearbox. In keeping with the motto “Power without Compromise”, it is now offered not only in two- and three-stage versions, but also in a one-stage version.

Compared to multi-stage variants, one-stage right-angle servo gearboxes have a more compact design and higher energy efficiency due to the reduced number of components.

Extended gear ratio options. For a wide range of applications.

The new one-stage version is available in gear ratios 2 and 4. In combination with the compact STOBER planetary gearboxes, solutions consisting of multi-stage gearboxes with ratios from 6 to 400 can be implemented. The previous gear ratio range has therefore more than doubled.

The KS right-angle servo gearbox features robust bearing technology, high-quality gearing technology and very high torsional stiffness. This makes it perfect for demanding applications with high dynamics.

Powerful. Flexible. Space-saving.

Thanks to low-friction bearing technology in the input, the KS gearbox achieves higher speeds across all variants than many competitors that rely on preloaded tapered roller bearings. In addition, the nominal torques have been increased by up to 20 percent. In combination with the smaller gear ratios, significantly higher output speeds are possible.

The two- and three-stage gearboxes can be combined with various STOBER motors via direct attachment. Thanks to the space-saving drive, operators benefit from less weight in addition to high torque and the resulting increased power density. The mass moment of inertia of the gearbox is lower due to the absence of the motor adapter, meaning that the full dynamics of the drive can be used.

“By adding planetary gearboxes, multi-stage variants can be implemented flexibly – according to the customer’s exact requirements. This modularity opens up completely new possibilities for individual drive solutions.”

– Artur Wagner, Director of Research & Development Mechatronics at STOBER.

“By adding planetary gearboxes, multi-stage variants can be implemented flexibly – according to the customer’s exact requirements. This modularity opens up completely new possibilities for individual drive solutions.”

– Artur Wagner, Director of Research & Development Mechatronics at STOBER.

The benefits at a glance.

- Increased input speeds thanks to low-friction bearing technology.

- Nominal torques increased by up to 20% for use in continuous operation.

- Optimal energy efficiency thanks to just one gear ratio stage.

- Extended gear ratio range for a wide range of applications.

- Robust, maintenance-free design for maximum reliability.

- High torsional stiffness for precise motion sequences.

- Modular design for maximum flexibility.

- Seamless integration into existing STOBER drive systems.

We would be happy to give you advice.

Please contact us!

This might also interest you

6th Generation Drive Controllers

Whether for high-performance systems, highly efficient multi-axis applications or compact modules – the 6th generation from STOBER always has the right drive controller on hand.

Play it safe with STOBER safety technology: Benefit from economical solutions with maximum safety, a wide range of functions and absolute flexibility.

Connected at a distance: The new STOBER hybrid cable reliably connects motors and drive controllers at 100 meters.