Apprenticeship as a Metalworking Specialist (m/f/d)

What do metalworking specialists do?

In your apprenticeship as a metalworking specialist (specializing in assembly technology), you assemble components into complete products — precisely, reliably, and using state-of-the-art technology. You’ll primarily work with metal, operate machines and tools, and make sure everything runs perfectly. Sounds dry? It’s not — because here, you’re really making things move!

Typical tasks in the daily routine:

- Basic skills: turning, milling, drilling, grinding (in the training workshop)

- Getting to know different areas according to your individual rotation plan: gearbox assembly, gearbox repair, servo motor assembly, high-bay warehouse, quality assurance

- Assembling and testing gear units and electric motors

- Active involvement in the daily operations of each department

- Optimal preparation for your future professional career

From day one, you’ll be actively involved — with real tasks, exciting projects, and room for your own ideas. Supported by experienced colleagues, you’ll grow professionally and personally, step by step, into your career.

Genuine interest makes the difference.

“A short internship, a quick look at the website, or a few well-placed questions during the interview can often make all the difference. Those who take the time to learn about the profession and the company show that they truly want it.

And that’s exactly what counts when starting an apprenticeship.”

– Ron Hagmaier, Trainer

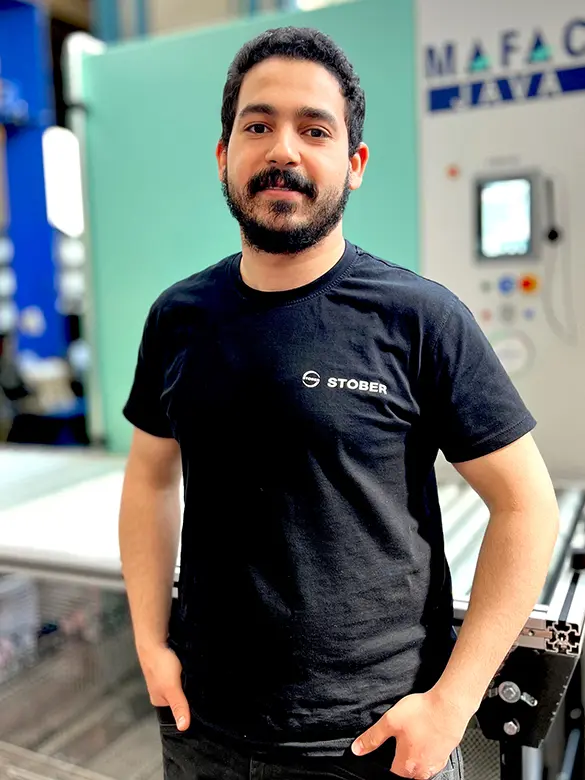

El-Akhdary Wadie

Apprentice Metalworking Specialist

Why did you choose this apprenticeship/occupation?

Because I enjoy hands-on work and have always liked working with my hands.

And why did you choose STOBER?

I applied to STOBER because the company was offering an apprenticeship position at the time—and because it’s an attractive company with an appealing line of work.

What does your typical week or day look like?

At the moment, I’m rotating through different departments, which means I’m learning the specific tasks of each area. For example, in the assembly department, I’m learning how to assemble gear units. I spend three days a week at the company and two days at vocational school.

What tasks and responsibilities do you have during your apprenticeship?

Mainly learning—first in the training workshop, where I gained basic skills such as drilling, turning, and milling. Now, in the specialized departments, I’m learning the specific tasks and workflows of each area.

What do you enjoy most about your apprenticeship/work?

A lot! I learn something new almost every day. I also really enjoy working with my colleagues—the sense of teamwork and mutual support is something I truly value.

What skills are important for this profession?

An interest in technology and good manual skills are definitely helpful. It also doesn’t hurt to have paid attention in math class!

What personal tips do you have for students?

Do internships and research the company beforehand if you’re invited to a job interview.

What makes the apprenticeship at STOBER special for you?

Since I started a previous apprenticeship in a different field, I know how much of a difference it makes when trainers truly care about their apprentices. Here, the trainers really take time to help us—for example, by supporting us with schoolwork or exam preparation.

The regular working hours and the flexible schedule are also a big plus!

More interesting info

Any questions?

Your contact person

Heike Grun

How do I apply for a job at STOBER? What is the application process like? What information should your documents contain?

As a family-owned company, it is very important to us to maintain close relationships and a basis of trust with our employees, customers, and partners. We put people first.

Meet STOBER at many trade shows, training fairs, and other events.