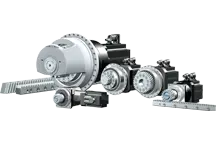

STOBER Products and Solutions

Everything from a single source

The STOBER drive system consisting of gear units, motors and drive controllers has a modular design and is freely scalable – for tailor-made, compact and powerful machine concepts. It can therefore be adapted to your individual requirements and combined as needed in nearly all industries and application areas.

Right-Angle Planetary Gear Units

When the motor gets in your way, you need planetary gear units coupled with highly efficient helical bevel gear units. For the highest dynamics, backlash stability and durability.

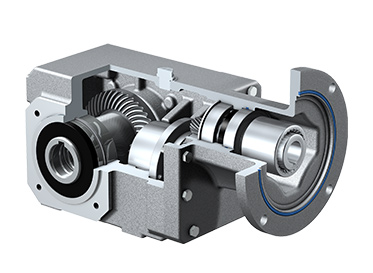

Power Transmission Helical Bevel Gear Units

A power transmission gear unit with high performance, a long service life and smooth operation. It’s ideal for angular transmission of motion and forces in small installation spaces.

Power Transmission Helical Gear Units

Helical gear units have an impressive design from a single mold. They can be attached quickly and easily to all common asynchronous motors – ideal for industrial use.

Power Transmission Offset Helical Gear Units

Compact, space-saving and absolutely powerful – the power transmission offset helical gear unit has extraordinarily smooth operation and high efficiency.

Everything from a single source

The STOBER drive system consisting of gear units, motors and drive controllers has a modular design and is freely scalable – for tailor-made, compact and powerful machine concepts. It can therefore be adapted to your individual requirements and combined as needed in nearly all industries and application areas.

Everything from a single source

The STOBER drive system consisting of gear units, motors and drive controllers has a modular design and is freely scalable – for tailor-made, compact and powerful machine concepts. It can therefore be adapted to your individual requirements and combined as needed in nearly all industries and application areas.

Right-Angle Planetary Servo Geared Motors

A high-precision right-angle planetary gear unit with an extremely compact servo motor – for small installation spaces.

Rack and Pinion Drives with Synchronous Servo Motors

From full rotation to linear: Innovative rack and pinion drives with synchronous servo motors from STOBER for ultra-compact, highly dynamic drive solutions.

Helical Bevel Servo Geared Motors

Helical bevel gear units and synchronous servo motors as an integrated, compact unit with very convenient installation dimensions and a high power density.

Offset Helical Servo Geared Motors

Looking for a geared motor for tight spaces? With a large axial distance?

Right-Angle Planetary Geared Lean Motors

Our right-angle planetary geared Lean motors – for high demands on durability, efficiency and service life.

Helical Bevel Geared Lean Motors

Save on everything without reducing performance and energy efficiency! STOBER helical bevel gear units combined with STOBER Lean motors.

Offset Helical Geared Lean Motors

Geared motors for tight spaces that are also extremely energy efficient, encoderless and include just one cable.

Asynchronous Helical Bevel Geared Motors

Asynchronous helical bevel geared motors have impressively convenient installation dimensions, high efficiency and a good energy balance.

Asynchronous Helical Geared Motors

This combination of a compact, economical helical gear unit and an IE3-class asynchronous motor for energy efficiency is a versatile jack-of-all-trades.

Asynchronous Offset Helical Geared Motors

Compact, absolutely rugged, with high efficiency and an IE3-classified asynchronous motor. Ideal for industrial applications that have limited space.

Everything from a single source

The STOBER drive system consisting of gear units, motors and drive controllers has a modular design and is freely scalable – for tailor-made, compact and powerful machine concepts. It can therefore be adapted to your individual requirements and combined as needed in nearly all industries and application areas.

6th Generation Drive Controllers

Tailor-made for any kind of drive task – with three mutually combinable SC6, SI6 and SD6 series, STOBER always has the right controller on hand.

Our experts – for your specific needs!

We are your partner when it comes to custom products. And we work with you to design high-quality solutions that fit your application exactly. Put your trust in our expertise.

Do you have special requirements for your drive when it comes to the motor and gear unit? No problem!

A selection of our customer-specific developments.

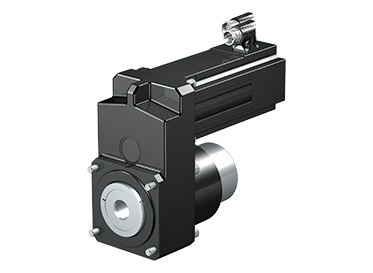

Offset helical gear unit with synchronous servo motor

Special offset helical gear unit for direct mounting on a synchronous servo motor.

With an extra-large axle distance for a spindle to be fed through.

Very short design.

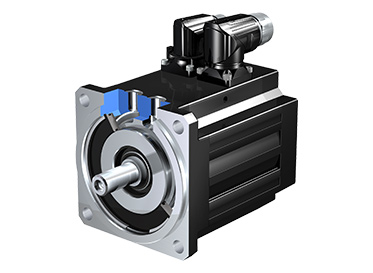

Synchronous servo motor for screw drives

Ultra-compact synchronous servo motors for screw drives, designed for universal attachment to threaded spindles from a wide range of manufacturers.

Designed with a clamping unit for fastening the threaded spindle; alternatively for direct drive of a threaded nut.

Synchronous servo motor with flange hollow shaft

Synchronous servo motor with large flange hollow shaft for the transmission of high forces and for conveying media.

With an optional permanent magnet holding brake.

Stainless steel gear unit

Extremely robust stainless steel gear unit, made of stainless steel and electropolished. This gear unit has been specially designed to withstand even the toughest cleaning requirements.

No maintenance, no water ingress, no oil leaks.

Geared motor with fan

Geared motor with a centrifugal fan integrated into the motor adapter. It cools the entire drive and thus enables operation at higher speeds.

And since the motor also benefits from the cooling effect, it can also deliver more power.

Synchronous servo motor with water cooling

With the same dimensions, water cooling enables an even more significant increase in performance compared to variants without cooling.

In addition, it reduces the heat transfer into the machine.

I’m interested

Make it yours! With the STOBER Configurator.

With just a few clicks, you can filter, compare, and configure your solution in real time. Simply save the configuration and share it with others.

Gear unit and motor combinations

Employees worldwide

Locations worldwide

Service partners worldwide

Industries and Applications.

We get your visions moving – in various industries and markets worldwide. Using a holistic approach for your specific task, we support you with precisely tailored solutions for drives and automation.

News from STOBER

- The best of both worldsSTOBER drive controllers combined with Siemens controllers for sophisticated motion control solutions.

- Modernization becomes child’s playSTOBER offers an all-in-one solution for controller- and drive-based applications with the CiA 402 device profil.

- Your partner for perfect motionSTOBER at SPS 2023.

EVENTS

Get to know us.

Take a look at our upcoming events.