Latest News

Enjoying the challenge

Posted on 27. March 2025

An inside look: Stephan Dilger, Head of Firmware/Software at STOBER

“Is 2025 looking up?”

Posted on 28. January 2025

Rainer Wegener on challenges in the industry, the market situation and future prospects.

Success in the aerospace sector

Posted on 13. January 2025

STOBER UK supplies drive technology for ultrasonic testing systems in use at Boeing.

Flexibility meets functionality

Posted on 4. November 2024

STOBER’s new compact SB6 drive controller for stand-alone applications.

A new level of safety

Posted on 30. October 2024

STOBER: Powerful SX6 safety module for SC6 and SI6 drive controllers.

Step by step to more quality of life

Posted on 26. September 2024

Higher efficiency, fewer breakdowns – STOBER continues to enhance its predictive maintenance capability.

Putting safety at the forefront

Posted on 24. September 2024

At SPS in Nuremberg, in Hall 3A, Booth 446, STOBER will present the SX6 safety module for SC6 drive controllers as well as the SI6 designed for multi-axis drive systems.

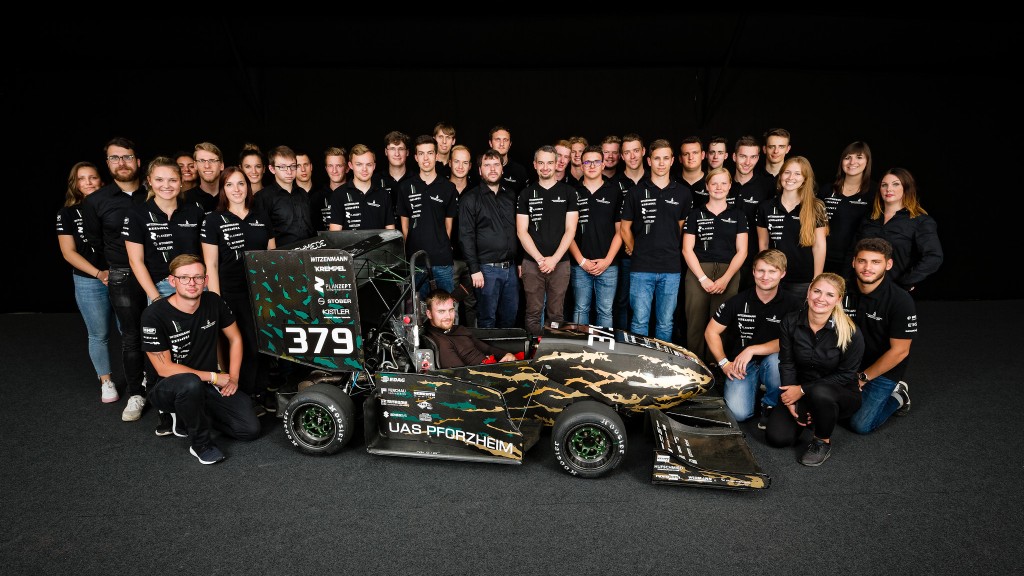

A Race Car Like No Other

Posted on 1. July 2024

Formula Student Electric: STOBER supports Rennschmiede Pforzheim as a main sponsor.

The best of both worlds

Posted on 23. November 2023

STOBER drive controllers combined with Siemens controllers for sophisticated motion control solutions.

Modernization becomes child’s play

Posted on 7. November 2023

STOBER offers an all-in-one solution for controller- and drive-based applications with the CiA 402 device profil.

STOBER supports Rennschmiede Pforzheim as a main sponsor

Posted on 28. July 2023

STOBER supports Rennschmiede Pforzheim as a main sponsor

A perfect win-win relationship

Posted on 20. June 2023

Hermle relies on drive technology from STOBER for automation solutions.

STOBER stays in the family

Posted on 27. March 2023

On March 1, 2023, there was a change in management at family-owned STOBER in Pforzheim, Germany. Rainer Wegener took over the management.

Precision in size XL

Posted on 1. March 2023

STOBER develops fourth generation of its large planetary gearboxes.

Planetary Gearbox Design with the FVA-Workbench

Posted on 24. November 2022

Planetary Gearbox Design with the FVA-Workbench: Reliable. User-Friendly. Efficient.

STOBER at SPS 2022: Efficient drive solutions on display

Posted on 11. October 2022

At the SPS 2022 is Nuremberg, STOBER will present various trade fair models in Hall 3A, Booth 446 that show how users can benefit from reliable, economical and powerful solutions.

Smoothing and cutting in one go

Posted on 8. September 2022

RAVNI TECHNOLOGIES relies on a complete drive solution from STOBER for a straightening and cutting machine for thin tubes.

A successful evolution: From rookie to fierce competitor

Posted on 16. August 2022

Lighter, faster, more efficient, more robust – these were the ambitious goals that the Rennschmiede Pforzheim racing team set itself with its new race car for 2022.

Acting with our finger on the pulse

Posted on 26. July 2022

Solukon relies on Lean geared motors from STOBER as a space-saving and robust drive solution.

The new compact

Posted on 13. May 2022

With the EZ2, STOBER rounds off its synchronous servo motors of the EZ series at the bottom end.

Predictive Maintenance: For a long, efficient service life

Posted on 5. April 2022

STÖBER Antriebstechnik GmbH + Co. KG has developed a feature for the predictive maintenance of its geared motors

PS6 goes big – for even more dynamics

Posted on 18. January 2022

STOBER offers the High Power supply module for drive controllers in multi-axis drive systems.

The bridge builder

Posted on 13. December 2021

An inside look: Rainer Wegener, Head of the Sales Management Center and member of the management team at STÖBER Antriebstechnik

The engineer who is on top of it

Posted on 26. November 2021

An inside look: Dr. Florian Dreher, Head of Development and Purchasing for Motors at STOBER.

STOBER is awarded with the TRUMPF Supplier Award

Posted on 19. November 2021

STOBER was awarded as the best supplier – among more than 800 strategic vendors of the TRUMPF Group. In addition to factors such as STOBER’s ability to deliver or its unique product quality, the extremely competent consulting service and the round-the-clock flexibility of STOBER employees were emphasized.

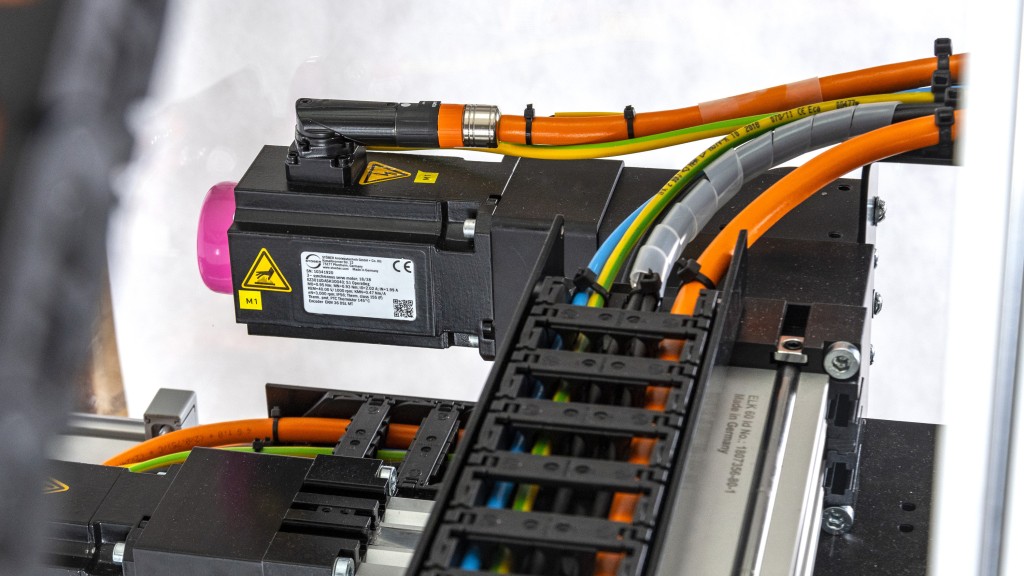

From full rotation into linear motion

Posted on 10. November 2021

STOBER: Rack and pinion drives with directly attached synchronous servo motors.

STOBER goes PROFIdrive and PROFIsafe

Posted on 25. October 2021

Use STOBER SC6 and SI6 drive controllers conveniently in PROFINET-based applications.

E stands for economy

Posted on 31. March 2021

STOBER has developed its planetary gearboxes of the PE series – where E stands for economy – even further. The user gets an extremely economical variant of the STOBER planetary gearbox with significantly increased performance and typical STOBER helical gearing. This gearing ensures low noise development and optimal smooth operation. This is a unique feature on the market in this price and product class. Combined with the STOBER IE5-class Lean motor with direct attachment, the user receives a drive that is economical, while still being extremely energy efficient.

Connected at a distance

Posted on 9. March 2021

STOBER: Transmit data and power up to 100 meters flawlessly with the One Cable Solution.

Good Ideas Pay Off

Posted on 2. February 2021

STOBER has started the new year with a good deed. Sterneninsel, the outpatient children’s and youth hospice service for the city of Pforzheim and the 28 Enzkreis communities, was pleased to receive a donation of 8,000 euros from the drive specialist from Pforzheim at the beginning of the week.

From another Point of View

Posted on 1. June 2020

STOBER presented the new generation of its servo planetary geared motors at the SPS IPC Drive in Nuremberg at the end of 2019. One of the special features of this generation: Each motor series can be directly mounted in any available size.

STOBER stays in touch – not only virtually!

Posted on 15. May 2020

The Corona crisis has changed life as it was, both in our professional and private life. The list of cancelled trade show is growing, not only in Germany, but worldwide.

Keeping Full Control

Posted on 29. April 2020

SOGA Gallenbach GmbH in Pforzheim, Germany, designs and develops special machines

The airlift against corona

Posted on 1. April 2020

The airlift against corona – Pforzheim companies fit mobile ventilators with STOBER components.

Far More Than Just a Planetary Gearbox

Posted on 1. April 2020

STOBER supplies customers not only with gearboxes, motors and drive controllers, but also complete automation solutions in addition to comprehensive support.

Tested and Documented

Posted on 6. March 2020

At the end of November 2019, STÖBER Antriebstechnik presented the new generation of its servo planetary geared motors for the first time at SPS IPC Drive in Nuremberg. These drives are the most compact on the market in their power range and with their exceptional diversity of combinations and options.

The Best of Partners

Posted on 1. March 2020

Leicht Stanzautomation develops and manufactures systems, such as for winding and unwinding strips and wires, and sells them around the world. For the first time, SI6 series drive controllers from STOBER are installed in the newest generation of the manufacturer’s automated multiple winders

The Total Package With Flexibility Guaranteed

Posted on 1. March 2020

DEMERO Automation Systems developed a three-axis CNC system to apply metered sealants during the production of various air-conditioning filters.

A Man Who Gets the Wheels Turning

Posted on 27. February 2020

STOBER is currently presenting the new generation of servo-planetary gearboxes, which are the most compact drives on the market in their power range and with their enormous diversity of combinations and options.

Rennschmiede Pforzheim – they have their concept

Posted on 25. February 2020

While the Rennschmiede Pforzheim team was previously represented at the Formula Student competition by a combustion-engine vehicle, it will enter an electric race car for the first time in 2020. This not only means a change in design

STOBER supports „Jugend forscht“

Posted on 3. February 2020

On 13 and 14 February the regional competition “Jugend forscht – Pforzheim/Enz” will take place on the campus of the university in Pforzheim. The aim of the event is to promote the innovative power, curiosity and inventiveness of young talents and to bring them together with experts from the respective faculties of the university and business within the framework of the competition.

For a good common cause

Posted on 1. January 2020

From January 19 to February 16 the “Vesperkirche”, a social project, takes place in a local church in Pforzheim. Many people come here during these days to eat, get help or just to have a roof over their heads. As part of their social activities, trainees and trainers from STOBER are supporting the event.

The Right Place at the Right Time

Posted on 29. November 2019

We saw tremendous success at SPS in Nuremberg, Germany. There, at the largest international trade show for electrical automation technology, we were able to generate many more new contacts as well as more leads than in years past. We presented our new generation of servo-planetary gearboxes for the first time on the 115 square-meter area.

Stäubli expands operating range of robots with STOBER axes

Posted on 1. November 2019

For precise, high-speed tasks, companies from industries such as the automotive, food, medicine, pharmaceutical, plastic or electronics sector rely on robots—e.g. for loading and unloading, palletizing, handling, sorting or stacking a wide array of components. Stäubli Robotics is one of the leading providers in the world. Additional axes from STOBER allow the multi-axis robots to be configured with complete freedom, thus giving them maximum flexibility. This is a partnership with a future—and significant added value for customers.

Cyber attack on STOBER web server infrastructure

Posted on 1. November 2019

Last week STOBER was hit by a cyber attack. The worldwide web server infrastructure was affected. Some of our web services are either limited or currently not available, such as downloads. Personal data is not affected.

We are actively working to restore the website as soon as possible. If you need information not available on the website, please contact +49 7231 582-0

Electricity in the blood

Posted on 18. October 2019

The Pforzheim University of Applied Sciences has had a racing forge for ten years.

STOBER develops new generation of planetary gearboxes

Posted on 1. October 2019

No Other Product is as Compact and Versatile. STOBER develops new generation of planetary gearboxes.

Mastering Complexity with Ease

Posted on 17. April 2019

Mechanical and design engineers are always pressed for time. Putting together just the right drive solutions is particularly time-consuming ─ especially if you have to gather and compare extensive manufacturer-specific documentation.

The Practical STOBER Forum – Trends. Innovations. Exchange.

Posted on 1. April 2019

On two days in March and April customers and interested parties participated at STOBER’s annual Practical Forum in Pforzheim. The event offers participants the opportunity to inform themselves about current trends and innovations in drive and automation technology. It’s also the perfect opportunity to exchange ideas, experiences and to discuss upcoming projects.

STOBER presents its new product configurator

Posted on 1. March 2019

With the new STOBER Configurator, users have an online tool to intuitively build the right drive solution from STOBER’s extensive product range with just a few clicks. Technical information and drawings are readily available after quickly and easily configuring a product. Users can even request a quote with a simple click. The configurator is one of many projects in STOBER’s commitment to supporting customers with additional digital services.

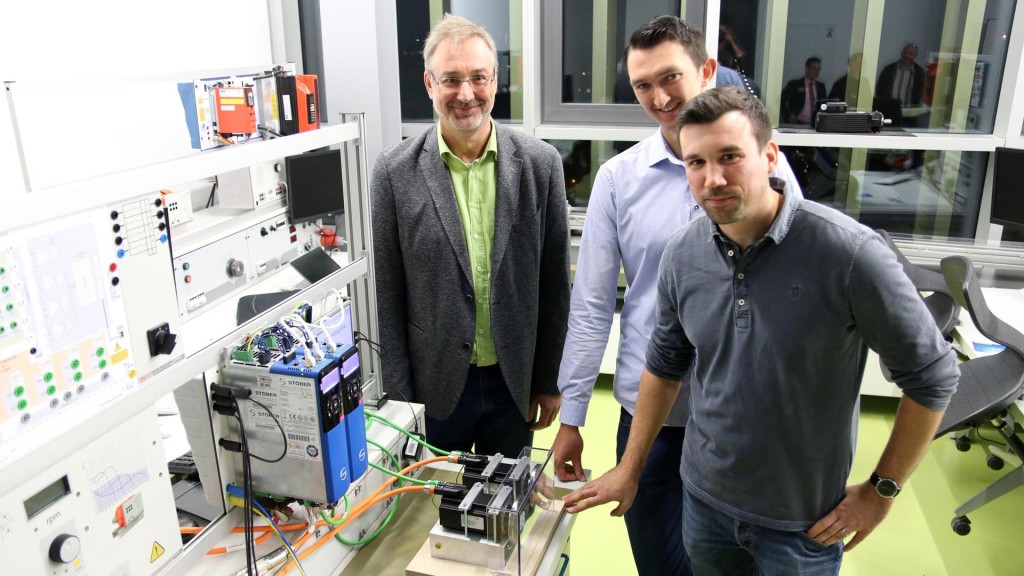

Successful collaboration with Heinrich-Hertz-Schule

Posted on 13. December 2018

Successful collaboration with Heinrich-Hertz-Schule in Karlsruhe:

SPS IPC Drives show in Nuremberg with STOBER

Posted on 4. December 2018

In light of the motto “better safe than sorry,” last week, STOBER presented the new SE6 safety module at the SPS IPC Drives trade fair in Nuremberg.

Play it safe with the SD6 drive controller

Posted on 12. October 2018

Powerful new SE6 ‘advanced safety module’ from STOBER integrates into SD6 drive controller for drive integrated safety functionality.

STOBER in Motion Mountain Bike Event

Posted on 24. June 2018

STOBER jersey on, helmet on and on your bikes!

That was the rallying call when the annual ‘STOBER in Motion’ mountain bike event rolled out for this year’s round. Organised for employees by employees, ‘STOBER in Motion’ is a mix of individual and team cycle races and 2018 was the 13th consecutive event.

New fully automatic robotic assembly plant

Posted on 19. March 2018

New fully automatic robotic assembly plant to manufacture the LeanMotor built using all STOBER drive technology.

Perfectly designed

Posted on 5. March 2018

The 6th generation of STOBER drive controllers provide the right solution for the increasingly complex requirements and functions in automation technology and machine engineering. New to the range is the SC6 stand-alone device, which enables extremely compact and economical application designs with up to four axes thanks to its integrated power supply and narrow structure. Design engineers now have access to three series from STOBER which they can combine and, that way, implement any conceivable task and a wide variety of applications. In addition to the new SC6, this includes the SI6 multi-axis drive controller and the flexible, extremely versatile SD6.

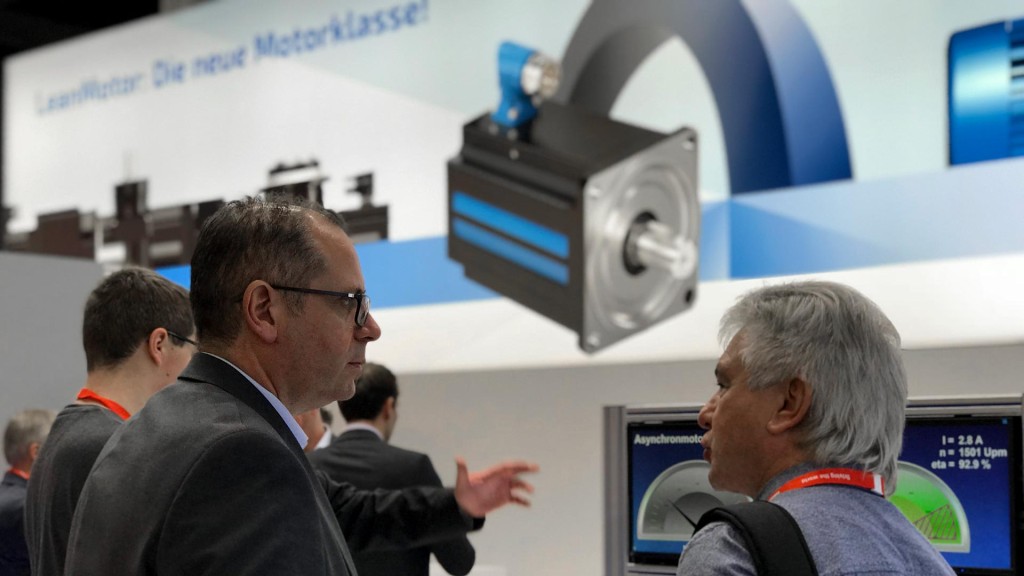

STOBER LeanMotor at SPS IPC Drives

Posted on 4. December 2017

The new LeanMotor took center stage for STOBER at this year’s SPS IPC Drives. “SPS IPC Drives is the most important trade show of the year for us,” explains Patrick Stöber. “It is a joy to present a world first this year and to see this much interest. We got visitors, customers and partners excited about our new development and had a lot of very interesting conversations.”

Finalist for the Motion Control Industry Award 2017

Posted on 20. April 2017

STOBER is announced finalist for the Motion Control Industry Award 2017 in the category Technical Innovation of the Year for its synchronous servo motors with hollow bore.

Innovations in series

Posted on 7. November 2016

Matthias Meyering, Head of Product Management Electronics: “Even more decisive than the sheer compactness of the SI6 is the omission of redundant supply units. The entire series of drive controllers is connected with a central supply module. The fuses and cabling for each individual axis are also dispensed with here. The drive controllers are connected with each other via Quick DC-Link modules. And by using double axis modules, unused power reserves of an axis can be used for other axes.”

Best Practices Award for STOBER Servomotors

Posted on 5. August 2016

STOBER wins the Best Practices Award 2016 for its powerful servomotors – having already earned the prize in 2014 with its PE planetary gearboxes and PS gearbox.

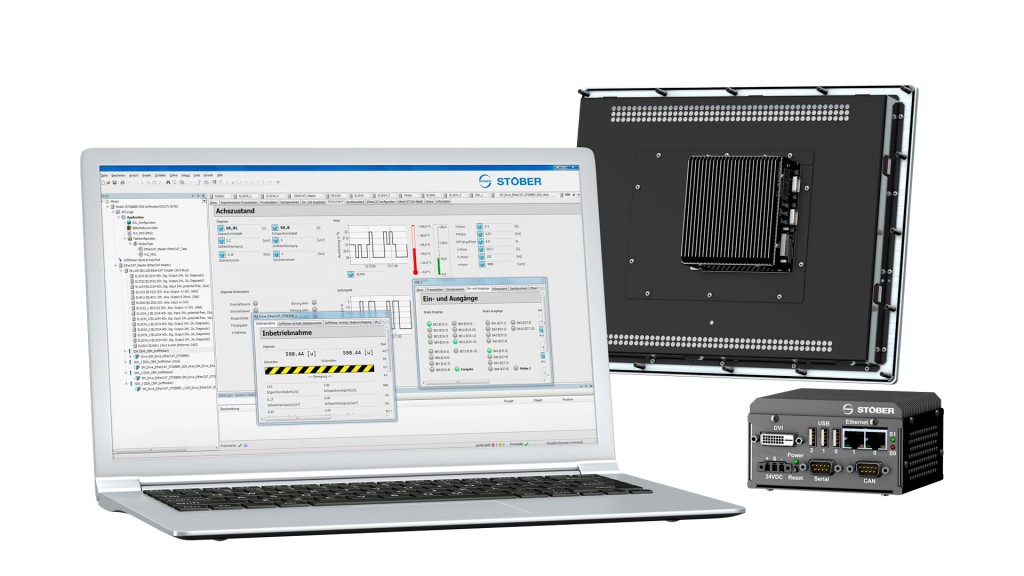

AS6 AutomationControlSuite

Posted on 22. June 2016

The Drive&Motion libs of STOBER are included for the efficient programming of a machine corresponding to IEC 61131-3.

STOBER expands its motion controller program

Posted on 31. October 2015

Ideal preconditions for highly dynamic drive solutions: STOBER expands its motion controller program.

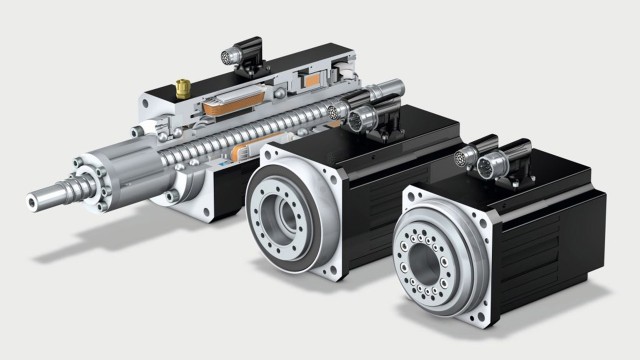

Innovative hollow shaft drives and screw drives from STOBER

Posted on 22. October 2015

Despite the size of the hollow shaft, these motors offer an exceptional power density with their orthocyclically linear-wound motor coils. The use of the flange hollow shaft for direct connection to the load results in a completely backlash-free, differentiated and smooth drive behavior.